OUR PRODUCTS

CUSTOM BOXES

We will size, sample and manufacture custom boxes exactly to your needs, measurements and budget. We produce very small cartons to large Gaylord cartons and many different styles and strengths of cartons with various board grades. Manufactured on the premises for speedy turnaround time on delivery

Custom Boxes are Our Specialty!

We make boxes sturdy enough to securely hold 200 pounds and insulated boxes to safely house your most fragile shipments. We also make pads, top or side-load boxes, storage boxes and we warehouse all types of packing materials such as shrink wrap, mailers, peanuts, bubble wrap—and so much more.

Let our design team help you create the best type of carton for all your shipping needs.

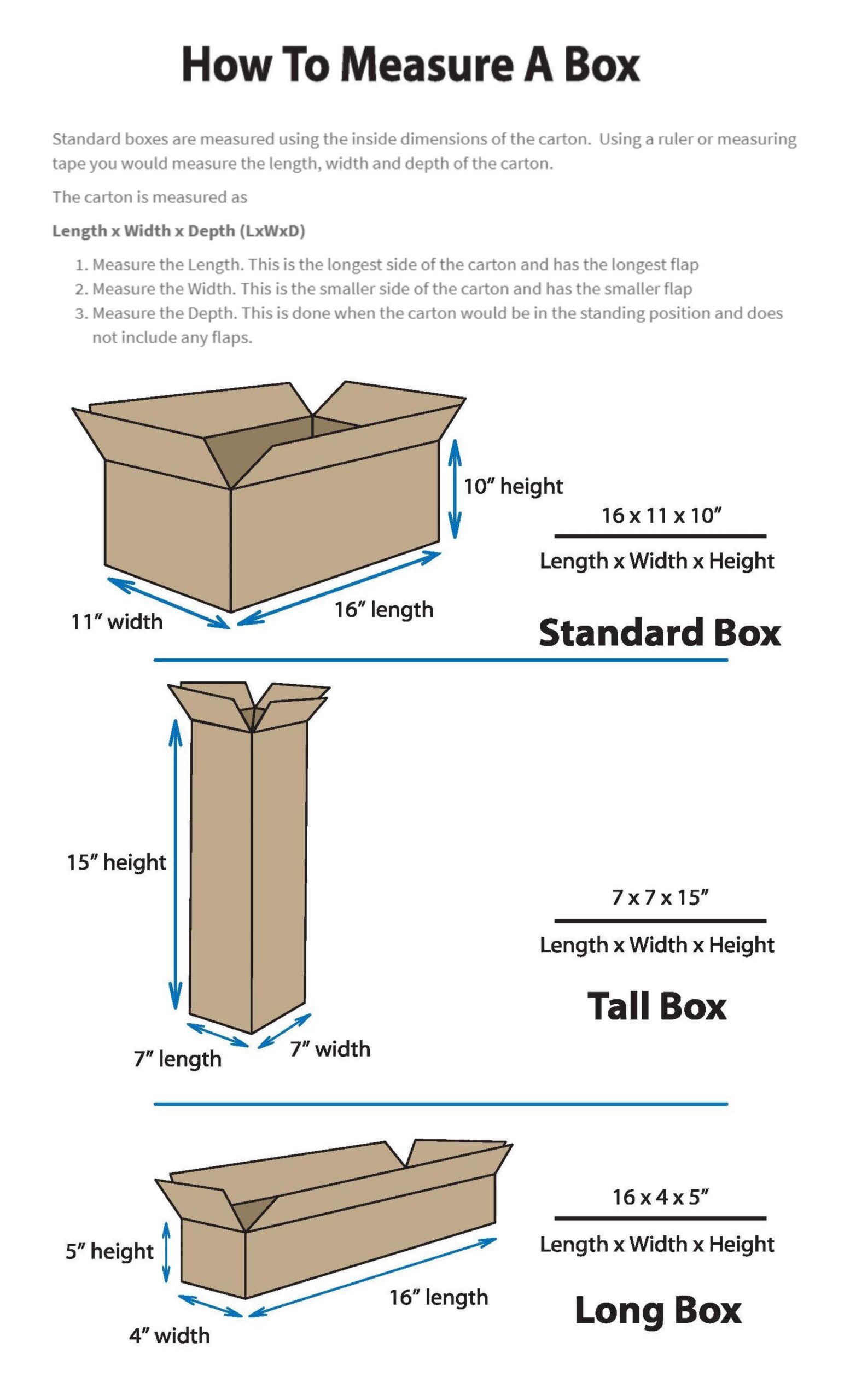

Boxes 101

Box Styles

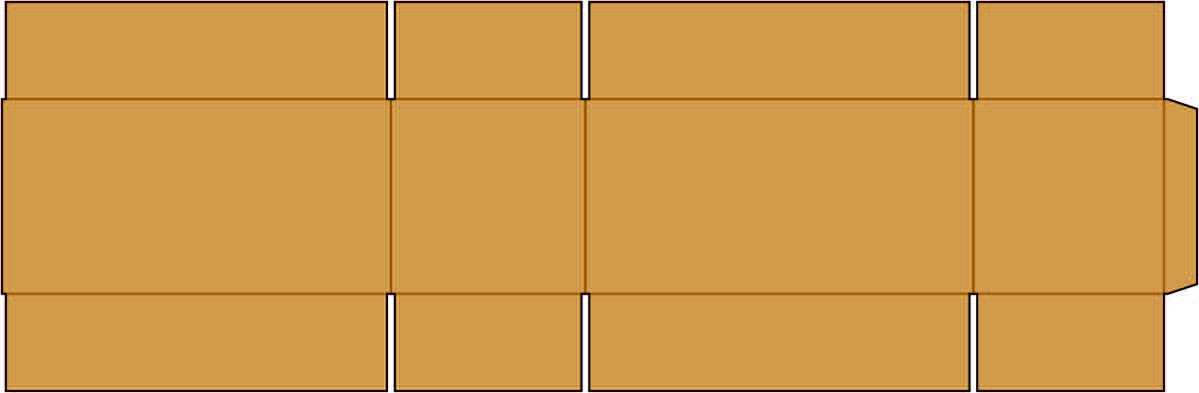

Five Panel Folder

A single cut and scored piece features a fifth panel used as the closing flap, completely

covering a side panel. The closed box has several layers of combined board on each end,

providing stacking strength and protection for long articles of small diameter which

might be damaged, or damage the box, if pushed through the ends.

Five Panel Folder

A single cut and scored piece features a fifth panel used as the closing flap, completely

covering a side panel. The closed box has several layers of combined board on each end,

providing stacking strength and protection for long articles of small diameter which

might be damaged, or damage the box, if pushed through the ends.

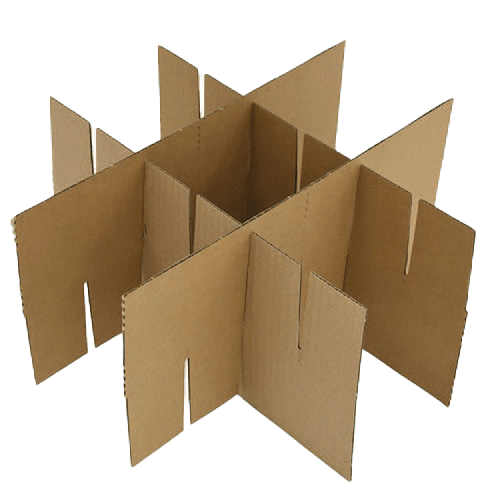

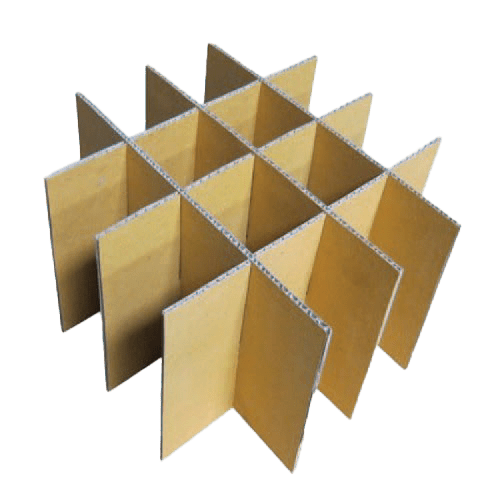

Partitions

Partitions or dividers provide a separate cell for each item in a box.

They are used primarily for glassware and other fragile articles.

Roll End Trays

Formed from a single piece of combined board, the design features an unbroken bottom, and several layers of corrugated in the end panels. Trays are not shipping containers. These would be used as inner containers.

Roll End Trays

Formed from a single piece of combined board, the design features an unbroken bottom and several layers of corrugated in the end panels. Trays are not shipping containers. These would be used as inner containers.

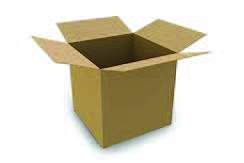

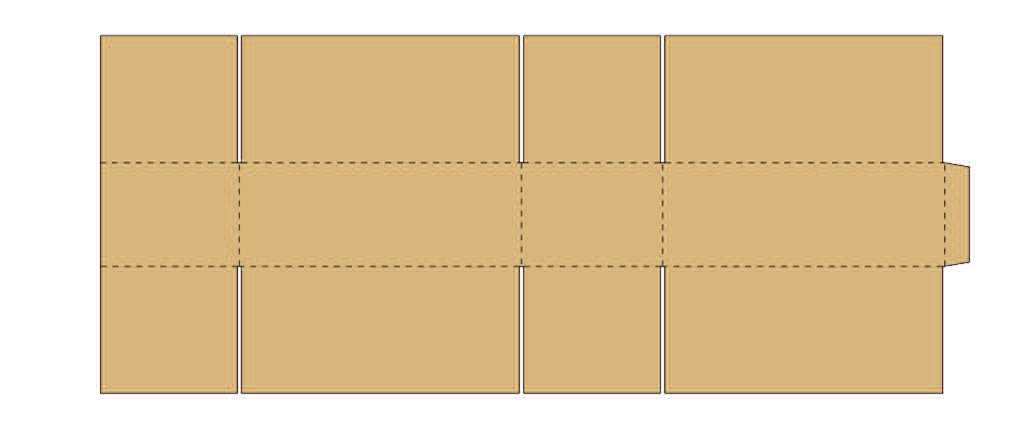

Regular Slotted Cartons (RSC)

All flaps have the same length and the two outer flaps (normally the lengthwise flaps) are one-half the container's width, so that they meet at the center of the box when folded.

Regular Slotted Cartons (RSC)

All flaps have the same length and the two outer flaps (normally the lengthwise flaps) are one-half the container's width, so that they meet at the center of the box when folded.

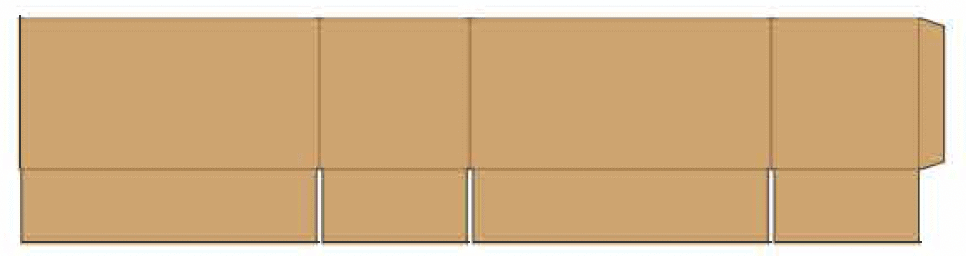

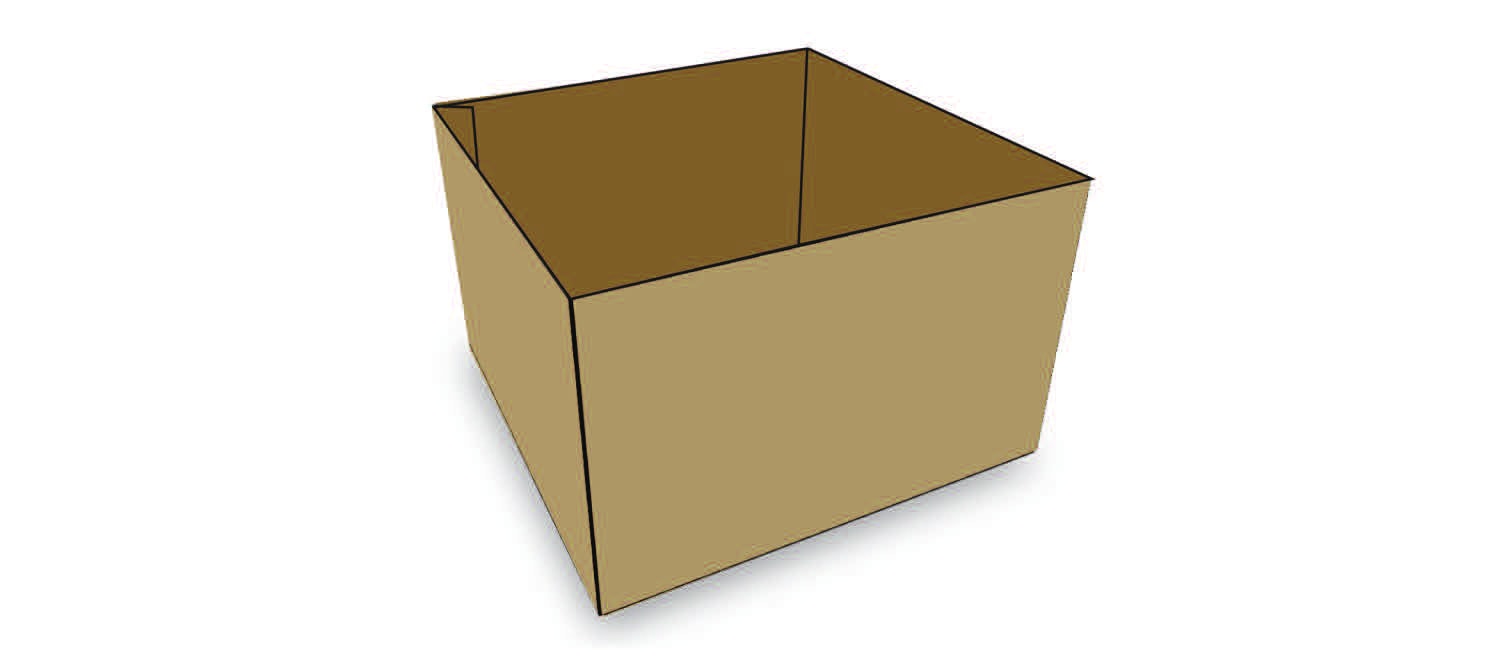

Half Slotted Cartons (HSC)

Same as Regular Slotted Cartons without one set of flaps.

Half Slotted Cartons (HSC)

Same as Regular Slotted Cartons without one set of flaps.

Full Overlap Carton (FOL)

All flaps have the same length (the width of the box). When closed, the outer flaps come within one inch of complete overlap. This style is especially resistant to rough handling. Stacked on its bottom panel, the overlapping flaps provide added cushioning. Stacked on its side, the extra thickness provides added stacking strength.

Full Overlap Carton (FOL)

All flaps have the same length (the width of the box). When closed, the outer flaps come within one inch of complete overlap. This style is especially resistant to rough handling. Stacked on its bottom panel, the overlapping flaps provide added cushioning. Stacked on its side, the extra thickness provides added stacking strength.

Full Telescoping Cartons

This two-piece box is made from two scored and slotted blanks (trays).

Full Telescoping Cartons

This two-piece box is made from two scored and slotted blanks (trays).

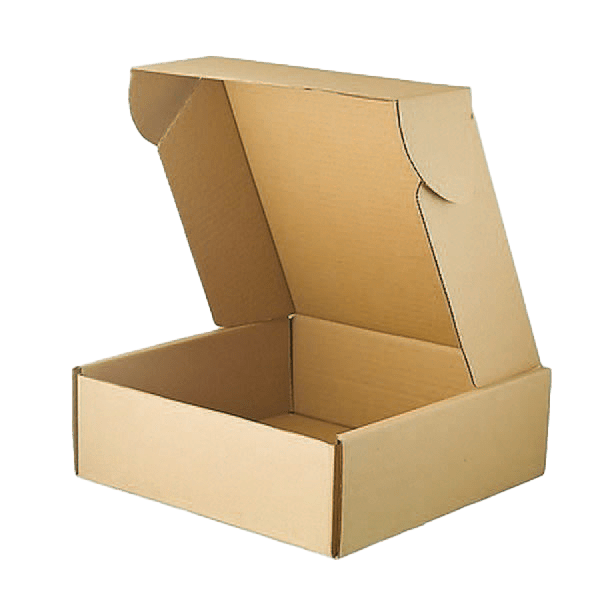

One Piece Folder (OPF)

One piece of board is cut so that it provides a flat bottom, with flaps forming the sides and ends, and extentions of the side flaps meeting to form the top.

One Piece Folder (OPF)

One piece of board is cut so that it provides a flat bottom, with flaps forming the sides and ends, and extentions of the side flaps meeting to form the top.

Printing

Printing on corrugated is an important feature in packaging design. There are a variety of different ways to apply graphics to corrugated board. We offer direct flexographic print.

Flexography

Flexible printing plates are mounted to a cylinder and pick up a fast drying water based ink from an anilox cylinder that is metered by a rubber roll or doctor blade system. Sheets are fed through the cylinders and graphics are transferred to the corrugated board. This is also known as direct print. There are a number of machinery alternatives available to converters and every converter is equipped a little differently. Flexography is also used in preprint applications where the printing is applied to the outside liner prior to being converted into a corrugated sheet. This process offers printing advantages but requires certain levels of volume before it can be considered an option.

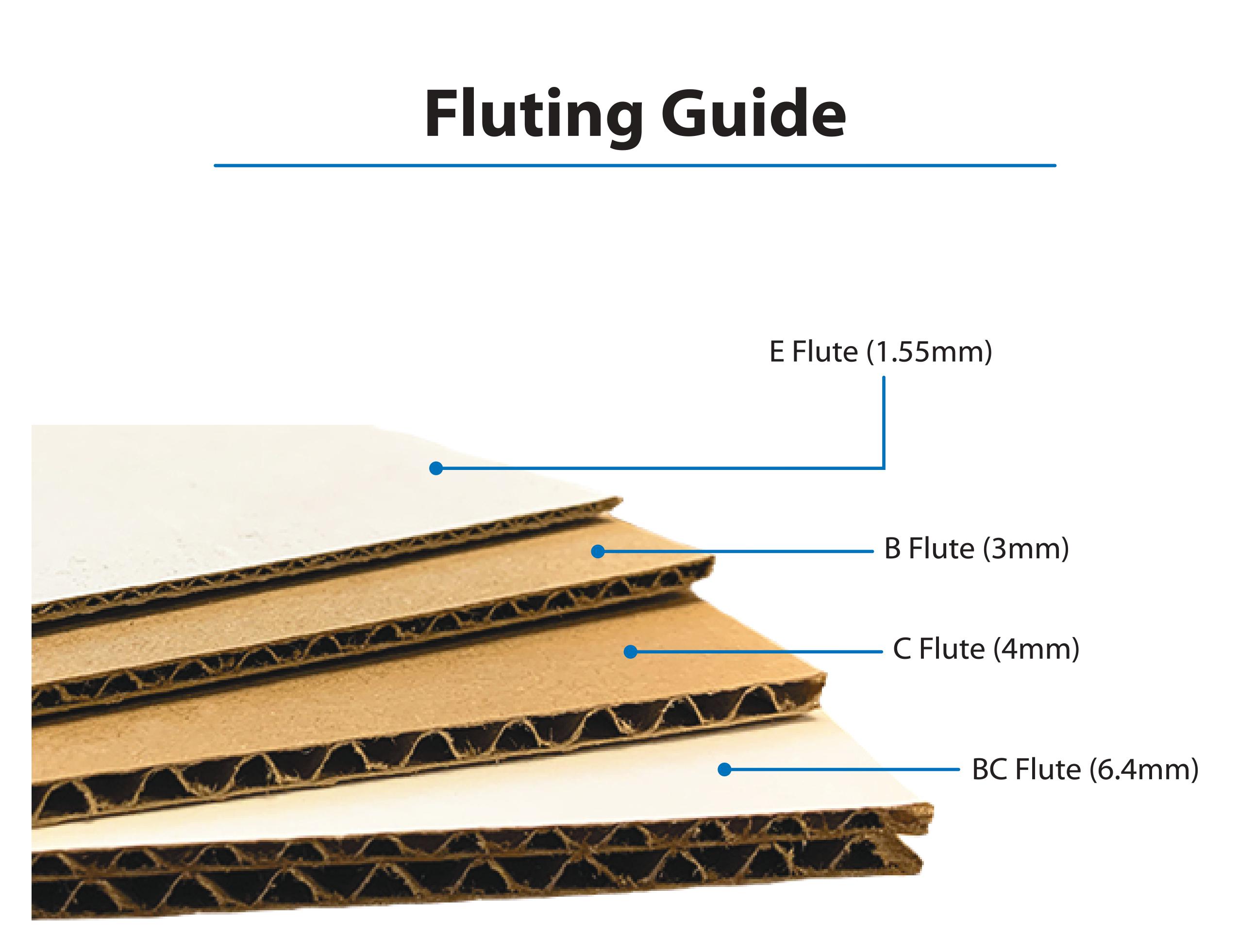

Structure (flutes)

Corrugated sheets are made up paper and starch. The fluted medium is bonded to the liners with a starch adhesive. Once bonded the combined board resists bending. The flutes provide cushioning when pressure is applied from the sides and when placed on end they form rigid columns capable of supporting a great deal of weight.

The most commonly used flutes are C and B flute. Generally, larger flutes offer greater vertical compression strength and cushioning. Smaller flutes offer printability advantages as well as structural advantages for retail packaging.

Types of Corrugated Fluting

We offer double wall and single wall fluting

Singlewall:

The corrugated medium is glued between two sheets of linerboard.

Doublewall:

Three sheets of linerboard with two mediums in between